Troubleshooting in Injection Molding

Abstract

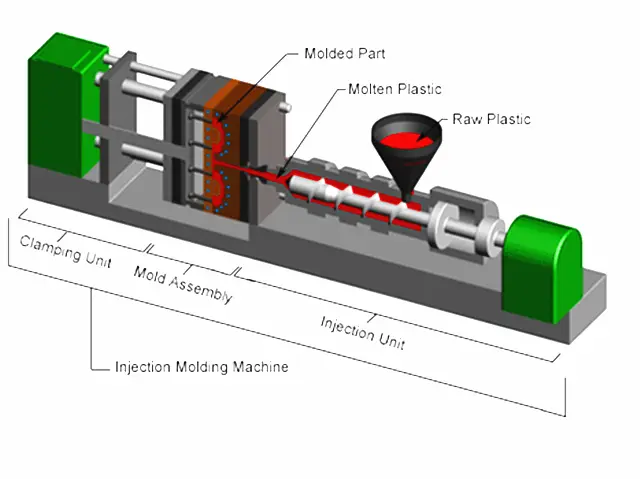

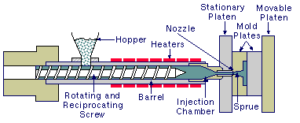

Injection molding is a complex manufacturing process that involves many variables. Any variation in these variables can lead to product defects. Therefore, it is important for manufacturers to be able to identify and troubleshoot injection molding problems.

This article provides an overview of injection molding troubleshooting. First, we will discuss some common injection molding defects. Then, we will discuss how to identify and resolve these defects. Finally, we will provide some tips on how to prevent injection molding problems.

Keywords: Injection molding, troubleshooting, defects, molding

Common Injection Molding Defects

Here are some common injection molding defects:

Short shot: This occurs when the molten plastic is unable to completely fill the mold. Short shots can cause defects such as thin walls, weld lines, and incomplete parts.

Short shot injection molding defect

Flash: This occurs when the molten plastic overflows from the mold. Flash can cause defects such as fins, sprue marks, and parting line flashes.

Flash injection molding defect

Voids: This occurs when air or other gases are trapped in the molten plastic. Voids can cause defects such as bubbles, sinks, and silver streaks.

Voids injection molding defect

Waves: This occurs when the molten plastic flows unevenly. Waves can cause defects such as surface roughness, waviness, and streaks.

Waves injection molding defect

Silver streaks: This occurs when additives or pigments in the molten plastic are not evenly distributed. Silver streaks can cause defects such as surface streaking and color mottling.

Silver streaks injection molding defect

Surface haze: This occurs when the mold surface is not smooth or is contaminated. Surface haze can cause defects such as surface roughness, cloudiness, and lack of gloss.

Weld lines: This occurs when two streams of molten plastic meet. Weld lines can cause defects such as seams, marks, and weak spots.

Weld lines injection molding defect

Bubbles: This occurs when air or other gases are trapped in the molten plastic. Bubbles can cause defects such as voids, holes, and thin walls.

Bubbles injection molding defect

How to Identify and Resolve Injection Molding Defects

Here are some common solutions for common injection molding defects:

Short shot: Increase injection pressure or injection time, decrease mold temperature, and use a more flowable material.

Flash: Decrease injection pressure or injection time, increase mold temperature, and use a less flowable material.

Voids: Decrease injection pressure or injection time, increase mold temperature, dry the material, and use vents.

Waves: Decrease injection speed, increase injection time, increase mold temperature, and use a more flowable material.

Silver streaks: Improve mixing uniformity, use more dispersed additives or pigments, and decrease mold temperature.

Surface haze: Clean the mold, use a release agent, and increase mold temperature.

Weld lines: Increase injection pressure or injection time, increase mold temperature, and use a more flowable material.

Bubbles: Decrease injection pressure or injection time, increase mold temperature, dry the material, and use vents.

Tips on Preventing Injection Molding Problems

Here are some tips on how to prevent injection molding problems:

The first step in identifying and resolving injection molding defects is to determine the type of defect. Once the type of defect has been identified, steps can be taken to correct the problem.

Use high-quality materials and molds.

Process the material at the proper temperature.

Use the correct injection pressure and injection time.

Keep the mold clean and dry.

Regularly inspect and maintain the injection molding machine.

Conclusion

Injection molding is a complex manufacturing process, but most problems can be prevented by following some simple guidelines. By understanding common defects and how to resolve them, manufacturers can produce high-quality injection molded products.

Note: This article is for informational purposes only. For more information on specific injection molding problems, consult a qualified professional.