How do you bring the mold cost down?

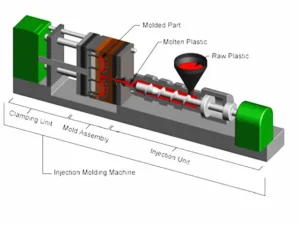

Injection molding is a popular manufacturing process for producing plastic parts. It is a versatile and cost-effective process that can create various parts, from small components to large housings. However, the cost of injection molds can be a significant barrier for startups.

The cost of an injection mold depends on some factors, including the size and complexity of the part, the material used, and the quality of the mold. A simple mold for a small part may cost a few thousand dollars, while a complex mold for a large part can cost tens of thousands of dollars or even more.

The high cost of injection molds can make it difficult for startups to bring their products to market. However, there are some ways to reduce the cost of injection molds and make them more affordable for startups.

The ways to reduce the cost of injection molds.

- Choose the right mold design

The design of the mold is one of the most important factors that affects the cost. A well-designed mold will be easier to manufacture and will require less material. This can save you money on both the mold itself and the parts that are produced from it.

There are a number of things to consider when designing an injection mold, such as the number of cavities, the type of gating system, and the ejection system. It is important to work with an experienced mold maker to design a mold that is both cost-effective and functional.

- Use simple features

Complex features, such as undercuts and thin walls, can increase the cost of the mold. If possible, try to design your product with simple features that are easy to manufacture.

- Choose the right material

The type of plastic used for the part can also affect the cost of the mold. Some plastics are more expensive than others, and they may also require special tooling or processes.

It is important to work with a material supplier to choose a plastic that is both cost-effective and suitable for your application.

- Use a Chinese mold maker

Chinese mold makers are often able to produce molds at a lower cost than mold makers in other countries. This is because they have lower labor costs and access to cheaper materials.

However, it is important to choose a reputable Chinese mold maker that can produce high-quality molds. You should also carefully review the contract to ensure that you are protected in the event of any problems.

- Consider alternative manufacturing processes

If the cost of an injection mold is too high, you may want to consider using an alternative manufacturing process, such as 3D printing or machining. These processes can be more expensive for small production runs, but they can be more cost-effective for larger production runs.

Injection plastic molding is a great way to manufacture plastic parts, but it can be expensive for startups. By following the tips in this article, you can reduce the cost of injection molds and make them more affordable for your business.

Here are some additional tips for reducing the cost of injection molds:

Get multiple quotes from different mold makers

Use standard mold components

Consider using a prototype mold

Pay attention to the surface finish

Communicate clearly with your mold maker

By following these tips, you can save money on the cost of injection molds and get your product to market faster.

Conclusion

Mold cavity is the part of the mold that shapes the plastic part. The size and complexity of the mold cavity will affect the cost of the mold.

China mould maker is a company that manufactures injection molds. Chinese mold makers are often able to produce molds at a lower cost than mold makers in other countries.

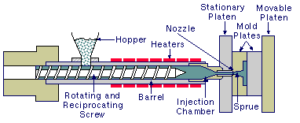

Injection plastic molding is a manufacturing process that uses pressure to inject molten plastic into a mold. The plastic cools and hardens in the mold, forming the desired part.

Injection mould fabrication is the process of manufacturing injection molds. This process involves a number of steps, including design, machining, assembly, and testing.